Profile

Main working fields:

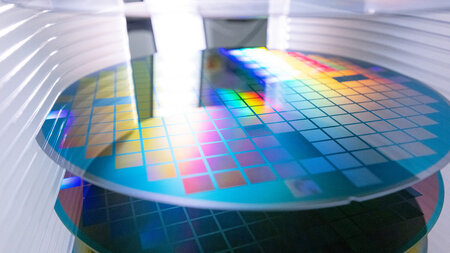

- Development of new materials and processes for metallization systems in micro and nanoelectronics

- Simulation and modeling of equipment and processes for micro and nanoelectronics as well as nano materials and nano structures

- Development of nanotechnologies, nano components and ultra-thin functional films

- Development of plasma processes for photovoltaics

- Development of technologies and components for microsystems and nanosystems (sensors, actuators and arrays)

- Processes and technology for integration of electronics and micro as well as nanosystem components

- Prototype fabrication of sensors, actuators and arrays

- Processing services for customer applications

Special attention is paid to Si-based MEMS technologies:

- Bulk technology

- High aspect ratio technologies, e.g. air gap insulated microstructures (AIM technology)

- Encapsulation by wafer bonding

- Encapsulation by thin film technology

Several high aspect ratio MEMS technologies, such as the patented AIM technology or the BDRIE (Bonding and Deep RIE) technology, have been established in order to fabricate high precision inertial sensors, e.g. acceleration, vibration and inclination sensors, as well as RF switches and RF resonators. High precision z-axis MEMS gyroscpoes are presently under development in co-operation with Fraunhofer ENAS and EDC Chemnitz. The robust design has been fabricated utilizing the BDRIE technology in combination with zero-level vacuum packaging by glass-Si Anodic bonding, with getter material inside the cavity (see fig. 1 and 2). Thus, the sensors benefit from capacitor gaps with aspect ratio > 50 and quality factors of more than 100,000 and provide high sensitivity (angle random walk < 5°/vh) and BIAS stability ( < 10°/h). Micromachined Fabry-Perot filters for the NIR range (3 ... 5 μm) for spectral analysis of gases have been fabricated for several years. Recently, in joint projects with Fraunhofer ENAS, InfraTec Dresden and Jenoptik LOC, further improvement could be demonstrated, e.g. extension of the measuring range to the 5 ... 8 μm and the 8 ... 11 μm window and achievement of dual band characteristics by integration of new optical materials. Presently the focus is put on establishing a robust technology for a new design with two moveable reflector carriers and smaller chip size on 6" wafers. Besides distributed bragg layers, the integration of nanostructures fabricated by nanoimprinting is under investigation. Special attention is paid to thin films ranging from several nanometers to a couple of microns in thickness. They are used as active and functional layers in micro electronic devices, as intermediate layers for packaging processes or protective coatings for micro machines or even as functional films in optical components like gratings or interferometers.