News

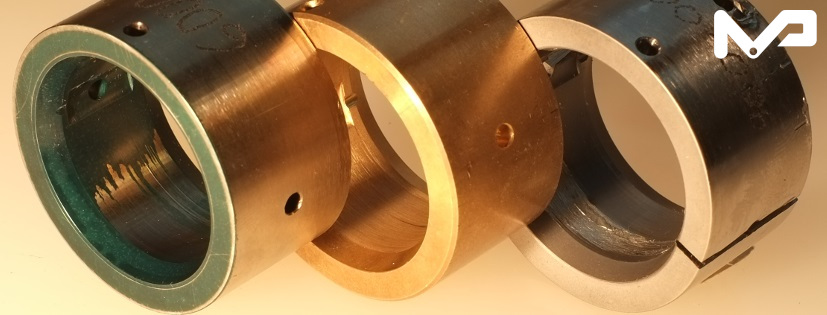

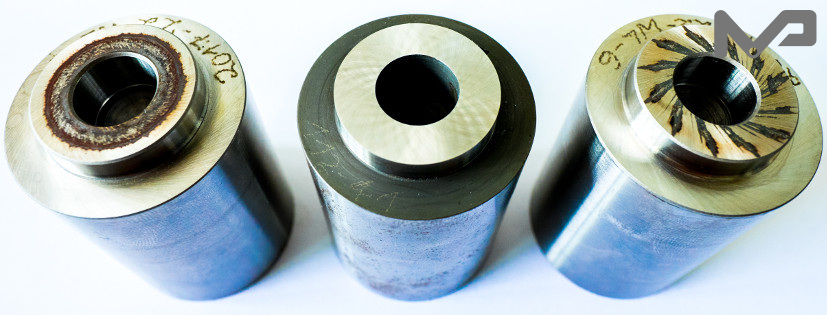

Bearing creep

Roller bearings are an essential component in machine systems. Point or line loads act in the bearing rings, which are superimposed with a rotation. The resulting elastic deformations of the bearing rings lead to a relative movement between the outer bearing ring and housing or inner bearing ring and shaft. This relative movement accumulates over time and can lead to wear in the contact surfaces. This phenomenon has been the subject of IKAT’s dynamic simulation research ever since. Numerous research projects deal with design methods and analyses to prevent ring creep.

Summer School Design Society

Ms. Nettlenbusch attends the Design Society’s Summer School in Malta, which is celebrating its 25th anniversary. The school teaches methods for writing a dissertation. The focus is on the development of research questions and the extraction of research hypotheses. At the same time, methods for self-organisation and structuring the dissertation were taught. An interdisciplinary exchange of researchers from different countries took place. We are looking forward to the next event of the Design Society.

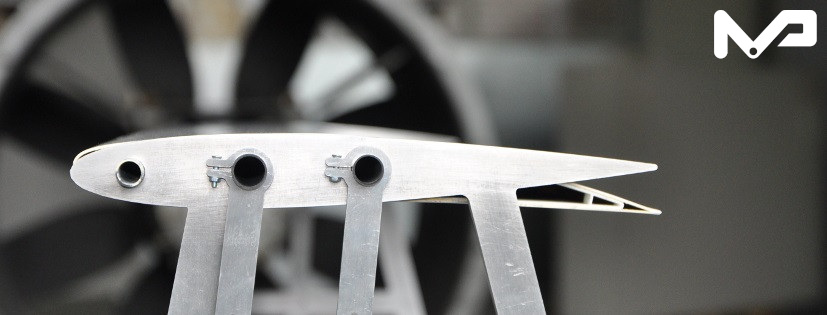

Multiaxial fatigue in contacts

The research issues associated with the fatigue strength of multi-axially loaded shaft-hub-connections (WNV) combine two important core topics that are continuously addressed at IKAT. On the one hand, complicated stress states, so-called non-proportional stresses, occur at the point of failure, which can only be evaluated using special strength hypotheses. In addition, tribological influencing variables, such as relative movement in contact (slip) and frictional shear stresses, lead to modified failure mechanisms, which are more critical to evaluate compared to classic/known notches on the free surfaces. Using the multiaxial test rig shown here, we are able to realize any application-specific superposition of rotating bending and cyclic torsion. Subsequent simulations and numerical interpretations of the experimental results of the stress-mechanical and tribological loading finally lead to calculation methods, which are suitable for engineers to estimate the contact strength in the fatigue analysis.

PA AK shaft-hub-connections @Clausthal University of Technology

From May 16-17, the WNV/strength section presented its research results at the PA AK WNV at TU Clausthal. In the domed building of the Aula Academica, topics of frictional and positive shaft-hub connections in particular were discussed and debated. The transfer of research into practice is an important function of the PA AK WNV, which is why many representatives from industry were present in addition to representatives from research institutes from all over Germany. We would like to thank the FVA and IMW for the constructive exchange and the excellent organization of the event.