News

IKAT’s BBQ

On July 10th, the student assistants and staff of IKAT came together for a fantastic barbecue evening. In a relaxed atmosphere, there was plenty of lively conversation, delicious grilled food, and the occasional cold drink.

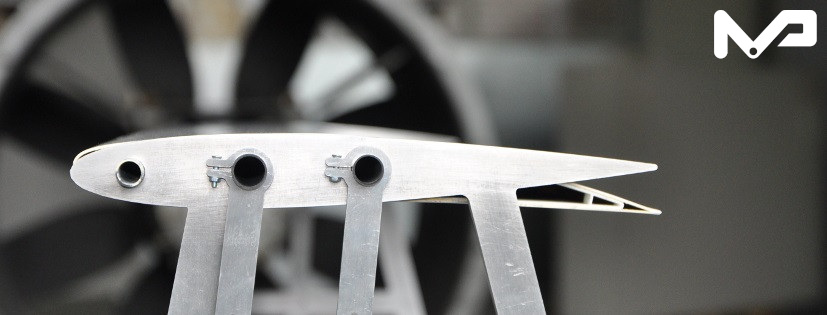

The undisputed highlight of the evening was the eagerly anticipated boßel challenge! The goal: to maneuver a machine element through a course with as few throws as possible—a task that required not only skill but also clever strategy. The flanges truly shined here, taking full advantage of their impressive rotational energy to outperform the rolling shafts.

A big thank you goes to our colleagues from the “Sustainable Products” research group for organizing this unforgettable event. We’re already looking forward to the next edition in 2026!

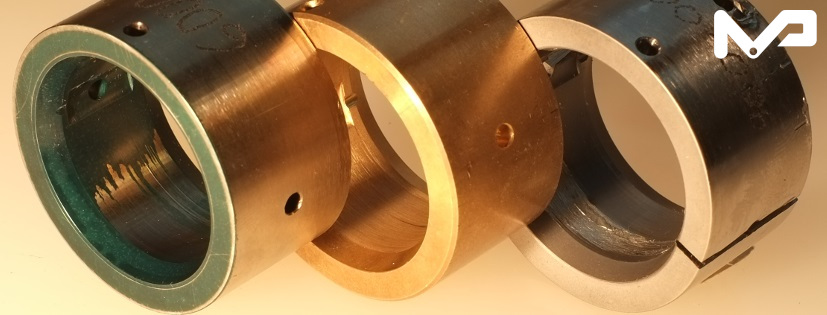

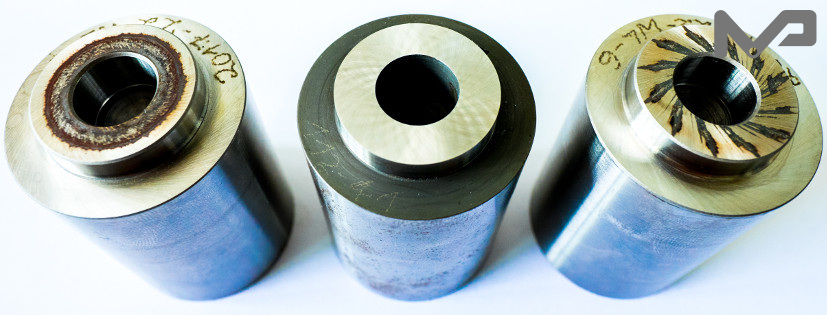

IKAT hosts meeting on plain bearings in european capital of culture

From 30th June-2nd July the IKAT hosted the PA AK Gleitlager in the european capital of culture Chemnitz. The intensive technical exchange of ideas was enhanced by a varied cultural program. You can see some cultural and technical insights in the short: We would like to thank the Plain Bearings Section for the excellent organization and the research associations FVA and FVV for taking on the patronage.

Makers United a Festival of technics

Despite the summer heat, Makers United once again attracted numerous visitors to the Chemnitz Stadthalle this year. Our stand with the interactive shadow play was well attended throughout. With a lot of curiosity and imagination, the guests developed their own creative solutions and even came up with new puzzles for the game. In addition to our contribution, many other exhibitors provided amazement and entertainment with interactive games, craft projects and animatronic creatures – an all-round successful festival for technology, art and hands-on fun!

International Conference on Multiaxial Fatigue and Fracture (ICMFF14)

The failure of components as a result of crack initiation and growth is no coincidence, but follows physical laws. Understanding these laws – especially under multiaxial, non-proportional loading and the complex phenomenon of fretting fatigue – is the subject of current research. The International Conference on Multiaxial Fatigue and Fracture (ICMFF14), which took place from 18 to 20 June at the Burkardushaus in Würzburg, was dedicated to precisely these topics. IKAT was represented with a paper on the effect of welding on crack growth in fretting fatigue, presented by our colleague Marius Müller. The subsequent discussion provided valuable impetus for further research directions and emphasised the importance of a deeper understanding of early failure. In addition, the conference impressively demonstrated the diversity of current approaches – from AI-supported service life assessment to the signalling analysis of complex crack processes – and promoted the exchange between research and industry. Many thanks to the organisers and contributors for the excellent organisation and the open dialogue.

Please see the conference paper https://doi.org/10.48447/ICMFF14-2025-16