Hard as construction steel, light as carbon, and yet all natural

Chemnitz scientists of the Federal Cluster of Excellence MERGE develop bio-based fiber-plastic-compounds for a future sustainable large-scale production

-

Lightweight-researcher Ahmed Amine Ouali develops bio-based fiber-plastic-compounds. Photo: Chemnitz University/Rico Welzel -

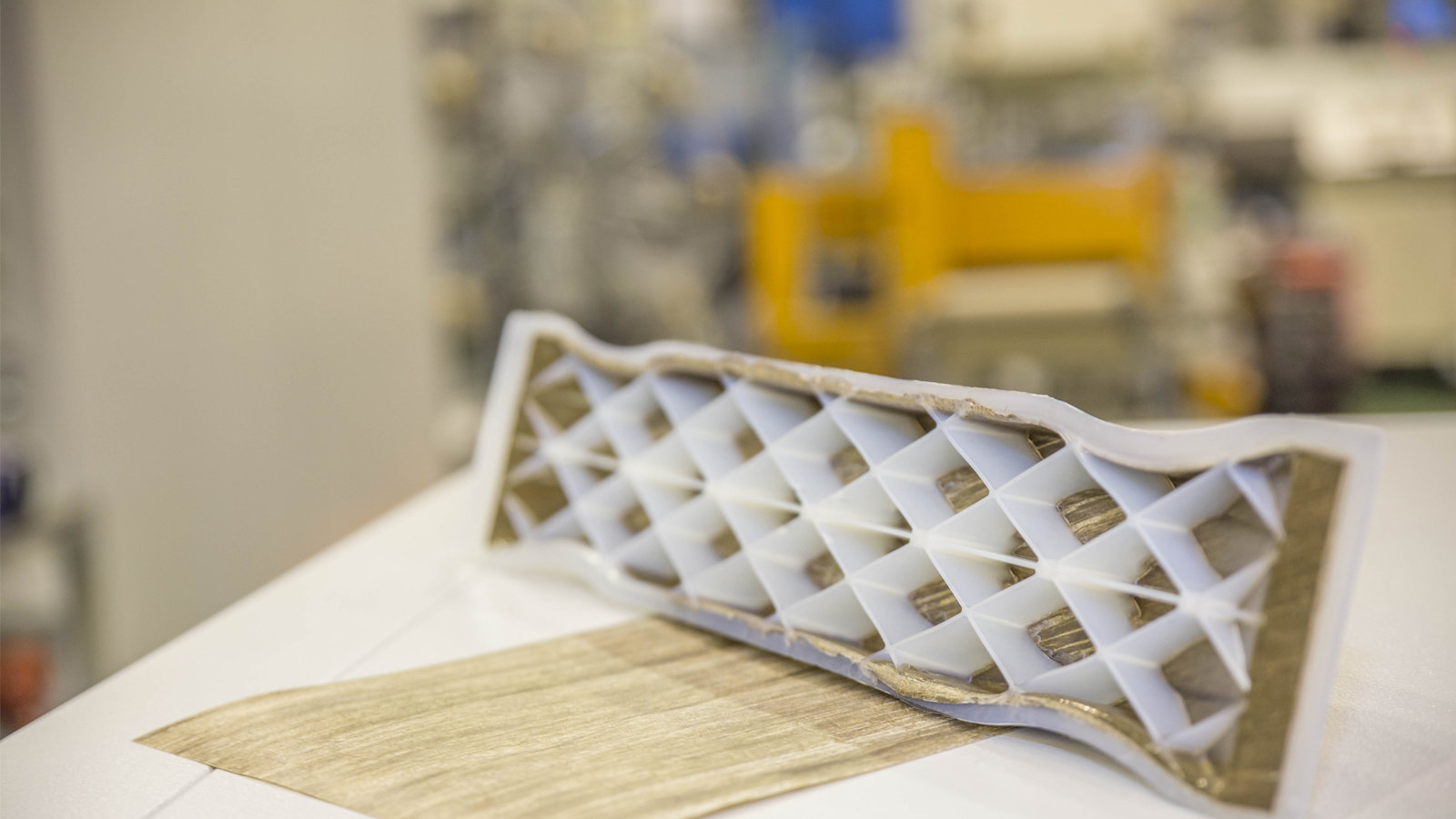

Demonstrator of a bio-based fiber-plastic-compound. Photo: Chemnitz University/Rico Welzel

Material compounds made from plastics and fibers are firmly established in the field of structural lightweight design. Glass and carbon fibers are most commonly used and for example integrated into thin films of thermoplastics as reinforcement. But most of these plastics are based on mineral oil – a rare resource whose extraction and use is harmful for the environment. A more ecological and sustainable approach is taken by the researchers in the Federal Cluster of Excellence MERGE. Ahmed-Amine Ouali, research associate at the Institute of Lightweight Structures explains the approach this way: “We replace the glass or carbon fiber with natural fibers such as flax. Our plastic matrix is a biopolymer of renewable resources. Thus, the carbon footprint in the product’s life cycle is significantly better.” Also the material characteristics with regard to the structural weight are technically interesting: The use of continuous filaments renders the compound extremely stiff and highly rigid in the direction of the fibers. Furthermore, flax is lighter than glass and cheaper than carbon fiber.

The researcher’s main objective was to develop a procedure with which the so-called semi-finished products made from plastics and natural fibers can be produced on large-scale. Film-stacking-technology - a discontinuous procedure – is currently common practice. In this procedure, single layers (for example plastic-film plus non-crimp-fabric plus plastic-film) are stacked into a heat press, fused under pressure, removed and further processed into plates in another machine. For the continuous procedure the MERGE researcher had to design a new rolling mill, a so-called calender. “Natural fibers have a special characteristic in contrast to glass or carbon fibers: they readily absorb fluids. Thus, prior to the processing they have to dry”, explains Ouali. “At the institute we developed a dryer plant that can be attached to the calender almost without space in between. This way the dried fiber has almost no contact to the moist ambient air.” The Omega-calender, named after its shape, is the core of the continuous production path. It consists of several cylinders through which the flax-fiber- plastic-films can theoretically be led continuously, heated up, and pressed together. After the impregnation process and the cooling of the so-called thermoplastic prepregs the fiber-matrix-semi-finished product, is complete. It is wound up on a role and can be further processed in various ways. Cut to size and with numerous layers pressed as a stack a rigid plate emerges. “We can also form the semi-finished product once more and combine it with injection molded products. Both in just one process. This way we produced our technology demonstrator, the lightweight carrier component”, illustrates Ouali.

The production procedure is currently intermittent, with a stop after the continuous production of the prepreg-semi-finished product. Depending on the researcher’s need the production then continues in numerous different plants. Yet, with regard to large-scale production, the manufacturing path can be supplemented or combined accordingly.

“We developed promising, sustainable, durable materials, whose production is significantly more energy-efficient and thus shows a better carbon footprint than in conventional fiber-plastic compounds”, says Ouali. Looking to the future he explains: “We will further experiment with various fiber structures as knitted or non-crimp fabrics, or in other forms and with different matrix combinations for example films or spun-bonded fabric.” That is how MERGE further develops and optimizes the positive material characteristics, ecological factors, and large-scale suitable production procedures.

Further information are available from Ahmed Amine Ouali, Professorship of Lightweight Structures and Polymer Technology at the Chemnitz University of Technology, phone +49 371 531 34332, email ahmed-amine.ouali@mb.tu-chemnitz.de

Matthias Fejes

05.07.2017